Reach out with your questions. We're here to support you.

Everything you need to know about the NFPA 70B…

What is the NFPA 70B?

The NFPA 70B, known as the Standard for Electrical Equipment Maintenance, details preventive maintenance for electrical, electronic, and communication systems and equipment. And while it’s been around since 1975, it’s become way more relevant in 2023. That’s because historically, the NFPA 70B has always been written as a recommended practice, including non-mandatory suggestions and using language like “should” or “should not.” However, the 2023 edition has been completely revamped and is now written as a Standard, now including mandatory language like “shall” or “shall not.”

Now that it’s a standard, what’s important to know?

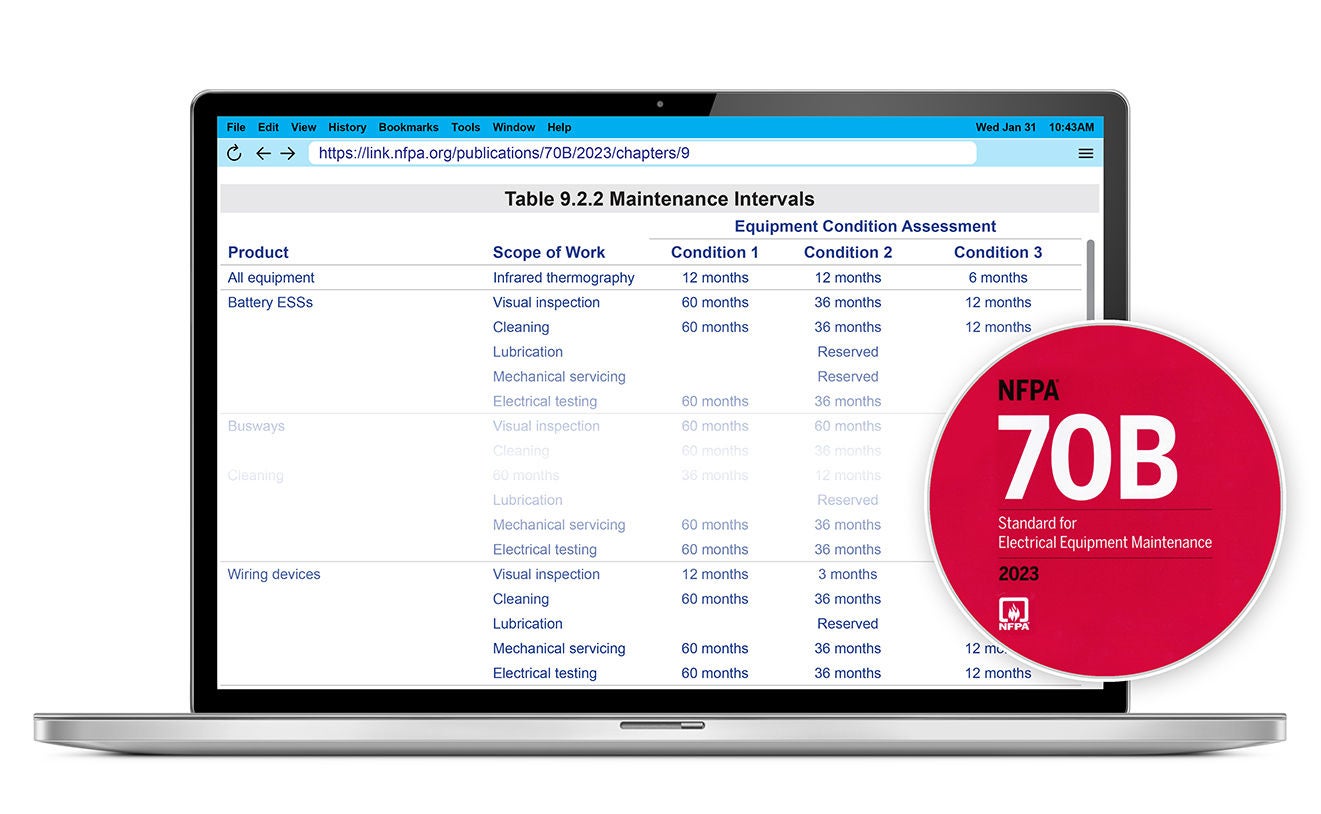

A critical portion of the NFPA 70B to be aware of is Chapter 9, which covers required maintenance intervals of equipment. Article 9.2.2 features a Table that identifies the required maintenance intervals for specific equipment categories, including battery ESSs, electric vehicle power transfer systems, electronic equipment, fuses, switchgear, wiring devices, and more. The required maintenance interval can range anywhere from required inspection before each use to a required inspection once every 60 months. The range is dependent upon the equipment’s physical condition, but in general, the better the condition of the equipment, the longer the time in between each required maintenance interval. Article 9.3.1 identifies the definition of different equipment physical conditions, including Equipment Physical Condition 1 (“like-new” conditions), 2 (maintenance results deviated from previous results, or minor issues have been identified), and 3 (maintenance has been missed the past 2 cycles, or issues or urgent actions have been identified).

What is the importance of identifying required maintenance intervals?

Staying up to date on required maintenance intervals is critical for several reasons. At a high-level, it helps ensure all equipment is unbroken and operating properly, improving OEE. By confirming this, it will trickle down into other benefits, including preventing safety hazards and increasing productivity.

NFPA 70, 70B, and 70E – What is the difference?

While they all sound similar, they are different standards that are all dependent on one another to ensure an electrical "Cycle of Safety."

NFPA 70, 70B, and 70E – How are they related?

Using all three simultaneously and correctly provides a complete electrical safety cycle. If one or more pieces are missing, it leaves the door open for a catastrophic accident. A good example of their interconnectedness is the electrical maintenance program (EMP). NFPA 70E requires an EMP, but the NFPA 70B Article 4.2 tells you how to build one. Together, these documents are more enforceable and strengthen the electrical safety cycle as prescribed by the NFPA.

Understanding the NFPA 70B as a professional

The NFPA 70B is critical to understand as a professional as it serves as a foundation for providing a service to customers, unlike NFPA 70E.

The Role of the Electrical Contractor

The Electrical Contractor plays a critical role in ensuring effective electrical safety cycles. Their unique position gives them visibility on both the practicality and necessity in implementing electrical safety cycles, making them a valued information source and advisor to facility management and construction teams. As a contractor, you can offer electrical maintenance as a part of your service offering and provide customers with guidance in the development of preventative maintenance plans.

The Role of the Consulting Electrical Engineer

The Consulting Electrical Engineer has a unique challenge – they must balance the complexity of system design and the constructability of a facility’s electrical systems with the need for NFPA 70B maintenance actions. The intimate understanding of NFPA 70B will allow the Engineer to be an effective advocate and innovation provider, tailoring the electrical system to meet operational needs while minimizing the time and financial impacts on both capital and operational expenses.